11.1. EtherNet/IP Overview¶

EtherNet/IP is an Ethernet-based communication protocol designed for industrial network communication. EtherNet/IP uses Common Industrial Protocol (CIP) over an Ethernet connection, typically through an RJ-45 connector. EtherNet/IP is widely used, especially in industrial settings, due to its large and fast data exchanges and community of support from Open DeviceNet Vendors Association (ODVA). The following terminology will be used throughout this document:

- Device

A device is any product that supports the EtherNet/IP protocol.

- Connection

A connection is a logic link between two devices to send and receive data.

- Orginator

An orginator (O) is a master device, or a controlling device, that initiates a request or a connection. PLCs or external software can be used as an EtherNet/IP orginator.

- Target

A target (T) is a device that receives a request or connection from the master. Multiple targets can be connected to one orginator on a network. Magna-Power products, that support EtherNet/IP, are target devices.

- TCP

TCP is a connected communication protocol that has error handling built-in. TCP requires that the orginator and target are both connected to each other and will exchange data in a multiple handshake format.

- UDP

UDP is a communication protocol that does not require a connection. UDP messages are rapidly sent over the network to a specific destination without error handling.

In the EtherNet/IP protocol there are two main types of communication: explicit messaging and implicit messaging. Each type of communication has supports different connections, traffic paths, and message formats, as shown in the chart below.

Messaging |

Form of messaging |

Protocol |

Connection |

|---|---|---|---|

Explicit |

Unconnected/Connected |

TCP/IP |

Class 3 |

Implicit |

Connected |

UPD/IP |

Class 1 |

For a more complete overview of EtherNet/IP and underlining standards, visit ODVA.org .

11.1.1. Explicit Messaging¶

Explicit messaging is used for non-realtime data exchange using request/response unicast messages handled with the TCP/IP protocol. Explicit messages are typical used for when the orginator device sends a request to read/write a value from/to a specific location on the target device. For example, a orginator could send an explicit message to set the device lock status. Requests from an orginator always result in a target response to indicate transaction success or failure.

The following parameters are needed in constructing an explicit message:

- Service Code/Name

The service code or the service name are required for requesting the action for the target device. For Magna-Power devices supporting EtherNet/IP, the service codes that are supported are Get Attribute Single (14 or 0x0E) and Set Attribute Single (16 or 0x10).

- Class ID

The class ID specifies the class object that data is being sent to or read from. For Magna-Power devices supporting EtherNet/IP, the class ID should be set to 162 (0xA2).

- Instance ID

The instance ID specifies the instance number of the above class object that is referenced in the request. All device supported instances can be found in the section Instances Listing.

- Attribute ID

The attribute ID specifies the attribute of the above instance referenced in the request. For Magna-Power devices, the attributes: Name (1), Access (4), and Value (5) are available. In most cases, the attribute ID should be set to 5.

11.1.2. Class 3 Connection¶

Class 3 connections are made only for explicit messages using TCP/IP. The connection parameters along with support communications paths are listed below. Detailed examples for explicit messages are provided in Explicit Messaging Example.

Parameter |

Value |

|---|---|

Number of Simultaneous Connections |

6 |

Supported RPI (Requested Packet Interval) |

100 ms to 10000 ms |

T →O Connection Types |

Point-to-Point |

O →T Connection Types |

Point-to-Point |

Supported Trigger Types |

Application |

Max. Supported Connection Size |

1526 bytes |

Supported Priorites |

Low, High |

11.1.3. Implicit Messaging¶

Implicit messaging is used for time-critical data exchange between a orginator and uses unicast or multicast messages handled with the UDP/IP protocol. The typical use case is when the orginator needs to set or query values on a target(s) in a controlled manner (cyclic and change-of-state ).

11.1.4. Class 1 Connection¶

Implicit messages must define a traffic pathways up front as it does not require responses from targets, which greatly reduces traffic. Connection paths are defined as either inputs or outputs with respect to the network. Inputs hold data received from the network, while outputs are data sent to the network. Only a subset of instances in Instances Listing can be include as inputs/outputs, which are listed below.

Name |

Instance |

Service |

|---|---|---|

13 |

Get |

|

257 |

Get |

|

258 |

Get |

|

513 |

Set |

|

515 |

Set |

Below lists the connection parameters for a Class 1 connection. A detailed example of an implicit messages sent cyclically, is provided in Implicit Messaging Example.

Parameter |

Value |

|---|---|

Number of Simultaneous Connections |

4 |

Supported RPI (Requested Packet Interval) |

1ms to 3200ms |

T→O Connection Types |

Point-to-point, Multicast, Null |

O→T Connection Types |

Point-to-point, Null |

Supported Trigger Types |

Cyclic, Change-of-State |

Max. Supported Input/Output Connection Size |

1448 bytes (Large Forward Open)

509 bytes (Forward Open)

|

Supported Priorites |

Low, High, Scheduled, Urgent |

The Electronic Data Sheet file contains multiple connection types, with Exclusive-Owner being the most flexible, since it offers bi-directional traffic. With Input Only connections, originator (s) can only hold data and never sends data out onto the network. Heartbeat connections, send small messages, over a fixed interval, in a single direction (either O →T or T →O). All the supported connection types are outlined below.

- Exclusive-Owner connection

This type of connection controls the outputs and does not depend on other connections.

Max. number of Exclusive-Owner connections: 1 Connection path O →T: Assembly Object, instance 0x96 (Default) Connection path T →O: Assembly Object, instance 0x64 (Default)

- Input-Only connection

This type of connection is used to read data from the target without controlling the outputs. It does not depend on other connections.

Max. number of Input-Only connections: Up to 4 (shared with Exclusive-Owner and Input-Only connections) Connection point O →T: Assembly Object, instance 0x03 (Default) Connection point T →O: Assembly Object, instance 0x64 (Default) Please note that if an Exclusive-Owner connection has been opened towards the module and times out, the Input-Only connection times out as well. If the Exclusive-Owner connection is properly closed, the Input-Only connection remains unaffected.

- Input-Only Extended connection

This connection’s functionality is the same as the standard Input-Only connection. However, when this connection times out it does not affect the state of the application.

Connection point O →T: Assembly Object, instance 0x06 (Default) Connection point T →O: Assembly Object, instance 0x64 (Default)

- Listen-Only connection

This type of connection requires another connection in order to exist. If that connection (Exclusive-Owner or Input-Only) is closed, the Listen-Only connection will be closed as well.

Max. no. of Input-Only connections: Up to 4 (Shared with Exclusive-Owner and Input-Only connections) Connection point O →T: Assembly Object, instance 0x04 (Default) Connection point T →O: Assembly Object, instance 0x64 (Default)

- Listen-Only Extended connection

This connection’s functionality is the same as the standard Input-Only connection. However, when this connection times out it does not affect application state.

Connection point O →T: Assembly Object, instance 0x07 (Default) Connection point T →O: Assembly Object, instance 0x64 (Default)

11.1.5. Electronic Data Sheet¶

When developing or using Ethernet/IP software to talk to a Magna-Power Electronics Anybus module, a electronic data sheet (EDS) should be used for device discovery and network setup. The is EDS a custom file created by the device manufacturer that describes communication parameters, available services, and device identification. The file may be requested as part of the setup process in PLCs or installing third-party software. The EDS can be download below and was use for Communication Examples.

11.1.6. Data Formatting¶

Byte Ordering EtherNet/IP must exchange properly formatted messages such that the targets can read requests. If the wrong number types or byte orderings are used, targets can misinterpretation data and respond unexpectantly. For example, the data entry for Hilschner EtherNet/IP Tool. For 16-bit words, bytes are ordered such that the significant bytes precedes the lower bytes in memory, which is standard little-endian. For 32-bit values, words are also ordered as little-endian, where the most significant word, precedes the least significant word. For a 32-bit value, 0x12345678, it should be sent as 0x78563412. Data is received following the same ordering. How software tools format data varies, and should be explored fully before testing.

Floating Point Data in transfered as a binary numbers (as opposed ASCII in SCPI Command Set) and needs a predetermined format for representing decimal numbers. For this, the widely adopted standard, IEEE-754, is used for storing floating point as a 32-bit values. For example, decimal number 3.14 is stored as 0x4048F5C3 in floating point. The number must adhere to the byte ordering conventions described previously. The final value of 3.14 would be sent as 0xC3F54840. Floating point numbers are received in the same format as they are sent.

11.2. Diagnostic and Simulation Tools¶

In this section, tools are discussed for simulating EtherNet/IP messages and connection classes on the network. Third-party software is recommended to act as the originator for these messages and is used extensively in later examples.

11.2.1. HMS IPConfig¶

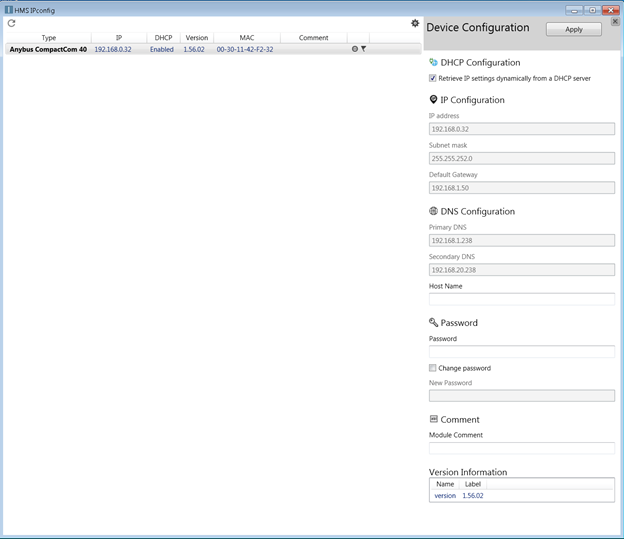

Magna-Power devices contain custom hardware that interfaces with an Anybus module. The Anybus manufacturer (HMS) provides a configuration tool called HMS IPconfig that is used exclusive to support their modules. This tool can help physically locate devices by blinking device LEDs, directly modify IP settings, upgrade module firmware. The software is available on HMS website listed in the below.

Fig. 11.1 HMS IPConfig¶

11.2.2. EtherNet/IP Web Page¶

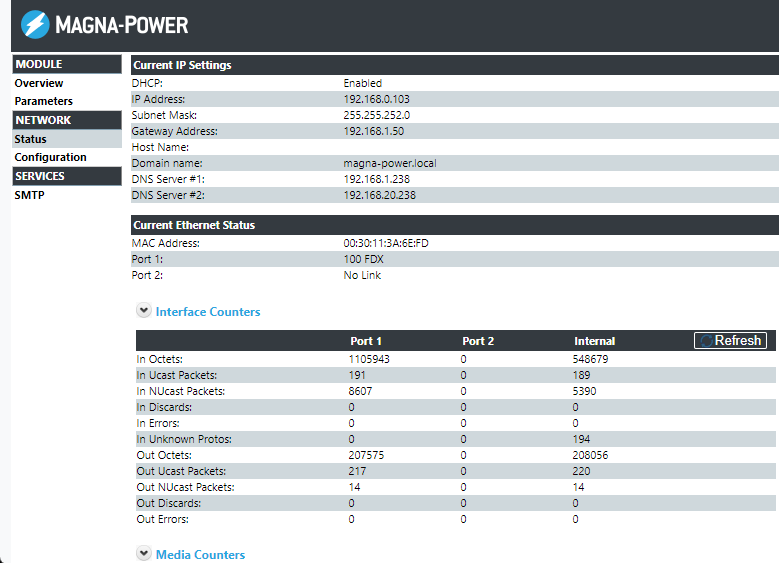

Each Magna-Power EtherNet/IP device hosts a web page for easily accessing local network settings, device parameters, and operation status. The user interface is organized into the side menus listed below.

- Overview

Shows basic information about the EtherNet/IP module, notably the device uptime.

- Parameters

Shows the available parameters that can be read or written to. Parameters with a button next to them indicates they are writable from the web interface. Allow time for the parameters to load, as several read and write requests are needed each time new parameters are loaded.

- Status

Displays the IP settings, Ethernet status, packets sent, and errors encountered. This page is largely for diagnostic purposes.

- Configuration

This page allows the IP configuration to be modified and saved to the device.

- SMTP

Not usable menu, feature incompatible with EtherNet/IP implementation.

The web page provides a secondary means of communicating with the device by simplify typing the device’s IP address in a web browser, as shown.

Fig. 11.2 EtherNet/IP web interface¶

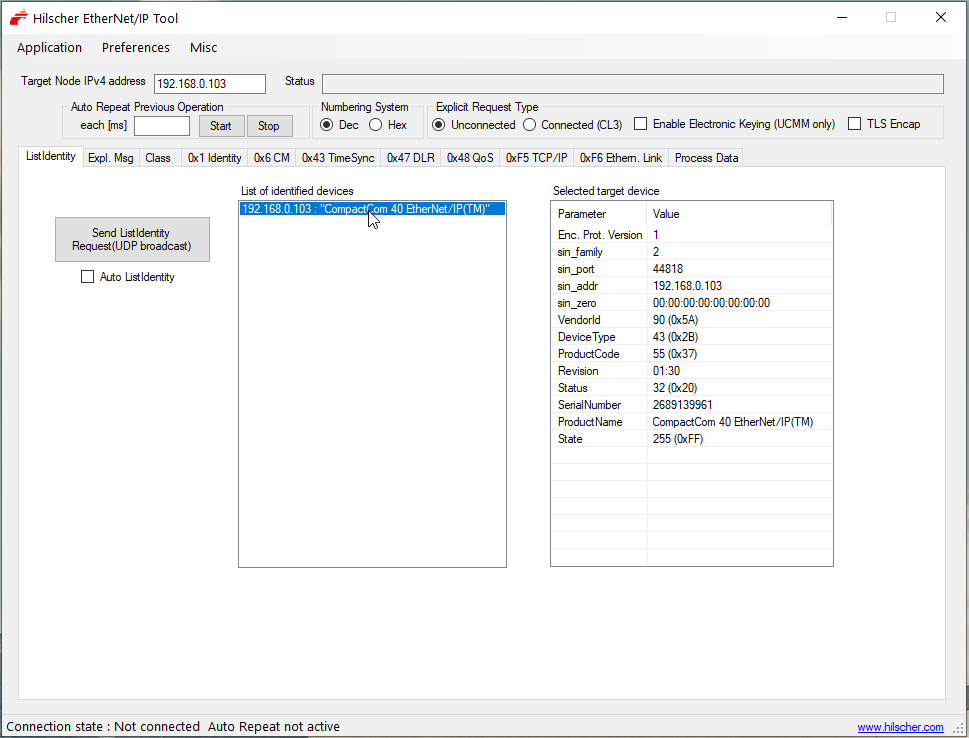

There are multiple way the IP address can be found. Navigating in the front panel menu system, Communication Settings. Or, using a router to find the assigned IP address by MAC address. Or, installing Ethernet/IP software that support auto-detection, like HMS IPConfig or Hilschner EtherNet/IP Tool, as shown. Tool is also simulates messages as used in Communication Examples.

Fig. 11.3 Discovery using Hilschner EtherNet/IP Tool¶

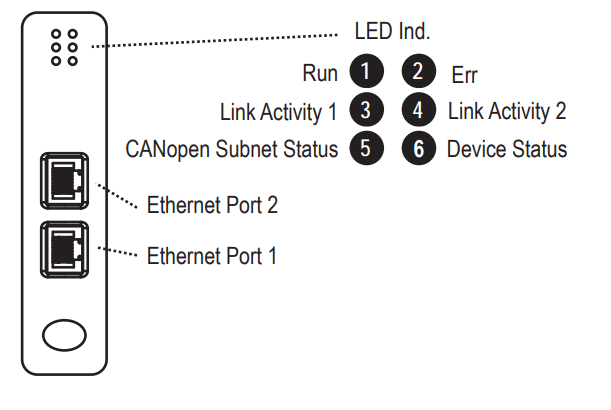

11.2.3. Device LED Codes¶

In rear of the Magna-Power product is a communications interface with two exposed bi-color LEDs. The LED labeled X indicates network status and one labeled Y indicates module status, as shown in LED indicators on rear interface. Status is indicated using colors and blink patterns, as shown in the tables below.

LED State |

Description |

|---|---|

Off |

No power or no IP address |

Green |

Online, one or more connections established (CIP Class 1 or 3) |

Green, Flashing |

Online, no connection established |

Red |

Duplicate IP address, FATAL error |

Red, Flashing |

One or more connections timed out (CIP Class 1 or 3) |

LED State |

Description |

|---|---|

Off |

No power |

Green |

Controlled by a Orginator in Run state and, if CIP Sync is enabled, time is synchronized to a Grandmaster clock |

Green, Flashing |

Not configured, Orginator in Idle state, or if CIP Sync is enabled, time is synchronized with Grandmaster clock |

Red |

Major fault, (EXCEPTION-state, FATAL error, etc.) |

Red, Flashing |

Recoverable fault(s). Module is configured, but stored parameters differ from currently used parameters. |

Fig. 11.4 LED indicators on rear interface¶

11.3. Communication Examples¶

Hilscher’s EtherNet/IP Tool is software than can simulate EtherNet/IP messages and send request to Magna-Power devices. Below are some examples using this software to demonstrate the different types of messaging.

11.3.1. Explicit Messaging Example¶

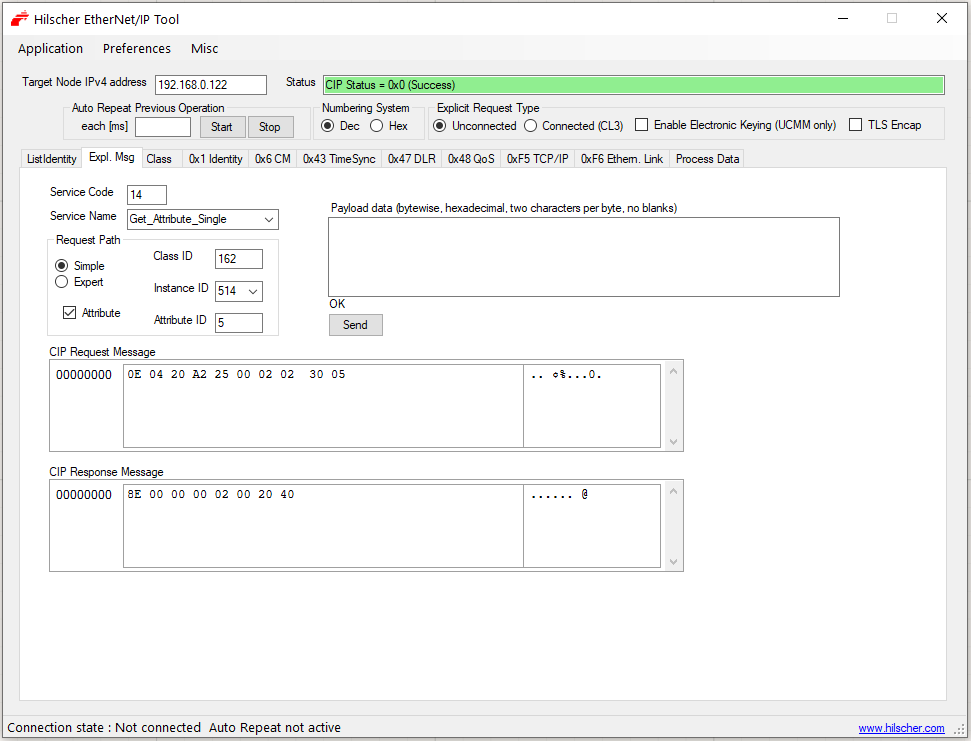

Explicit messages involves simple request-response traffic between the originator and target. In Explicit read example, a request for the Setpoint Current (Instance #514) is sent and a response value 2.5A (0x40200000) is returned.

Fig. 11.5 Explicit read example¶

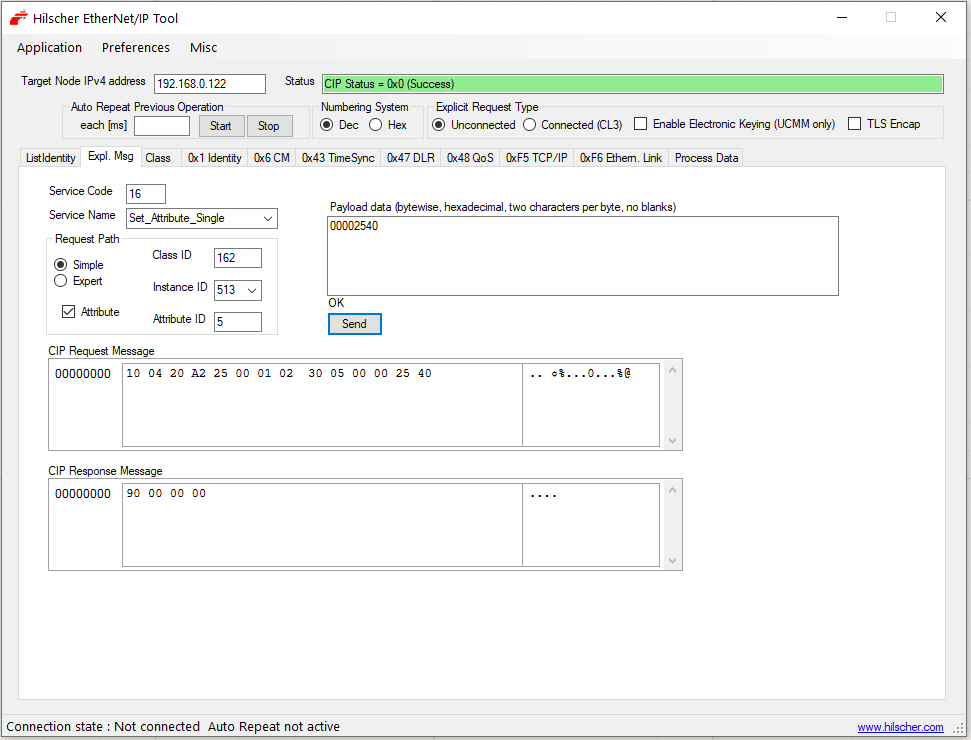

In Explicit write example, the value for the Setpoint Current (Instance #513) is updated with 2.578125A (0x40250000) and a CIP write response acknowledges the operation.

Fig. 11.6 Explicit write example¶

11.3.2. Implicit Messaging Example¶

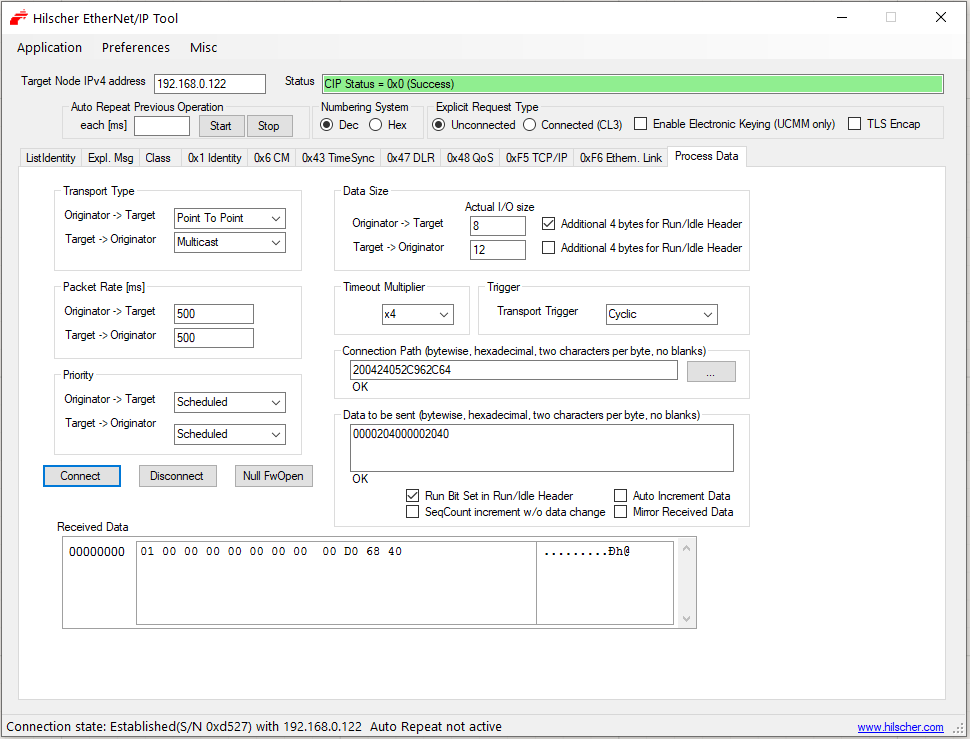

The following is a typical use case example for implicit messaging, where the set point voltage and set point current are cyclically updated, and the terminal voltage, terminal current, and status register are measured concurrently. Hilschner EtherNet/IP Tool was used to construct the message and to act as the orginator. The connection path settings are listed below. Message needs to formatted as little-endian, as was discussed in Data Formatting. The fields labeled Actual I/O size must be sized to fit the traffic and checkboxes Additional 4 bytes for Run/Idle Header and Run Bit Set in Run/Idle Header must be checked, as shown in Implicit message example.

Object |

Instance |

Name |

Attribute |

Supported Services |

|---|---|---|---|---|

Assembly (0x04) |

100 (0x64) |

Input |

Data (3)

Size (4)

|

Get Attribute Single (14)

Set Attribute Single (16)

|

150 (0x96) |

Output |

Data (3)

Size (4)

|

Get Attribute Single (14)

Set Attribute Single (16)

|

|

5 (0x05) |

Configuration

(Used in Forward Open)

|

Data (3)

Size (4)

|

Get Attribute Single (14)

Set Attribute Single (16)

|

Name |

Value |

Data Type |

Value (Big-Endian) |

Value (Little-Endian) |

|---|---|---|---|---|

Setpoint Current |

45.0 |

32 bit Floating Point |

0x42340000 |

0x00003442 |

Setpoint Voltage |

100.0 |

32 bit Floating Point |

0x42C80000 |

0x0000C842 |

Name |

Value |

Data Type |

Value (Big-Endian) |

Value (Little-Endian) |

|---|---|---|---|---|

Status Register |

262209 |

32 bit Integer |

0x00040041 |

0x41000400 |

Terminal Current Measurement |

44.77724 |

32 bit Floating Point |

0x423316F9 |

0xF9163342 |

Terminal Voltage Measurement |

100.0365 |

32 bit Floating Point |

0x42C812BD |

0xBD12C842 |

Fig. 11.7 Implicit message example¶

11.4. Instances Listing¶

EIP Command |

Write Instance |

Read Instance |

Description |

|---|---|---|---|

Operation Commands |

|||

N/A |

11 |

Returns the value of the Questionable Status register |

|

N/A |

13 |

Status Register |

|

17 |

N/A |

Enables or disables the DC input based on parameter setting |

|

Measurement Commands |

|||

N/A |

257 |

Measures and returns the average current at the sense location |

|

N/A |

258 |

Measures and returns the average voltage at the sense location |

|

N/A |

259 |

Measures and returns the instantaneous DC power at sense location |

|

N/A |

260 |

Measures and returns the instantaneous resistance at sense location |

|

Setpoint Commands |

|||

513 |

514 |

Sets the current set-point |

|

515 |

516 |

Sets the voltage set-point |

|

517 |

518 |

Sets the power set-point |

|

519 |

520 |

Sets the resistance set-point |

|

Trip Commands |

|||

769 |

770 |

Sets the over current trip (OCT) set-point |

|

771 |

772 |

Sets the over voltage trip (OVT) set-point |

|

773 |

774 |

Sets the over power trip (OPT) set-point |

|

775 |

776 |

Sets the under voltage trip (UVT) set-point |

|

Slew Commands |

|||

1025 |

1026 |

Sets the rising slew rate for current when in current regulation state |

|

1027 |

1028 |

Sets the rising slew rate for voltage when in voltage regulation state |

|

1029 |

1030 |

Sets the rising slew rate for power when in power regulation state |

|

1031 |

1032 |

Sets the rising slew rate for resistance when in resistance regulation state |

|

1033 |

1034 |

Sets the falling slew rate for current when in current regulation state |

|

1035 |

1036 |

Sets the falling slew rate for voltage when in voltage regulation state |

|

1037 |

1038 |

Sets the falling slew rate for power when in power regulation |

|

1039 |

1040 |

Sets the falling slew rate for resistance when in resistance regulation state |

|

Control Commands |

|||

1281 |

1282 |

Enables extended power range |

|

1283 |

1284 |

Sets the control mode |

|

Function Generator Commands |

|||

1537 |

1538 |

Sets the desired function for the integrated function generator |

|

1539 |

1540 |

Sets the amplitude for the sinusoid function |

|

1541 |

1542 |

Sets the DC offset from zero for the sinusoid function’s midline |

|

1543 |

1544 |

Sets the period for the sinusoid function |

|

1545 |

1546 |

Sets the low level amplitude for the square function |

|

1547 |

1548 |

Sets the high level amplitude for the square function |

|

1549 |

1550 |

Sets the period that the square function remains at the low level amplitude |

|

1551 |

1552 |

Sets the period that the square function remains at the high level amplitude |

|

1553 |

1554 |

Sets the low level amplitude for the step function |

|

1555 |

1556 |

Sets the high level amplitude for the step function |

|

1557 |

1558 |

Sets the low level amplitude for the ramp function |

|

1559 |

1560 |

Sets the high level amplitude for the ramp function |

|

1561 |

1562 |

Sets the period for the ramp function to transition from low to high level amplitude |

|

1563 |

1564 |

Sets the period for the ramp function to transition from high to low level amplitude |

|

Configuration Commands |

|||

1793 |

N/A |

Restores the factory EEPROM data |

|

1795 |

1794 |

Locks and unlocks the product from configuration and set-point changes |

|

1798 |

1799 |

Configures the sense location and automated compensation values |

|

1802 |

1803 |

Sets the setpoint source |

11.4.1. Operation Commands¶

11.4.1.1. StatusQuesQ¶

This command queries and returns the values of the Questionable Register. This read-only register holds the live (unlatched) questionable statuses of the MagnaLOAD electronic load. Issuing this query does not clear the register. The bit configuration of the Questionable Register is shown in the table below.

- Write Instance

11

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Integer

Questionable Register

Bit |

Weight |

Abbreviation |

Description |

|---|---|---|---|

0 |

1 |

OVP |

over voltage protection, hard fault |

1 |

2 |

OCT |

over current trip, soft fault |

2 |

4 |

OVT |

over voltage trip, soft fault |

3 |

8 |

OPT |

over power trip, soft fault |

4 |

16 |

OCP |

over current protection, hard fault |

5 |

32 |

OTP |

over temperature protection, hard fault |

6 |

64 |

RSL |

remote sense loss, hard fault |

7 |

128 |

CC |

constant current regulation, regulation status |

8 |

256 |

CV |

constant voltage regulation, regulation status |

9 |

512 |

CR |

constant resistance regulation, regulation status |

10 |

1024 |

CP |

constant power regulation, regulation status |

11 |

2048 |

SFLT |

soft fault, the ord value of all soft faults |

12 |

4096 |

HFLT |

hard fault, the ord value of all hard faults |

11.4.1.2. StatusRegQ¶

This command queries the Status Register. This read-only register holds the live (unlatched) operation status of the MagnaLOAD electronic load. Issuing a query does not clear the register. The register location and definitions are subject to change after any firmware release to accommodate new features. The Questionable Register is a subset of the status register and does not change between firmware updates. The present bit assignments are shown in the table below.

- Write Instance

13

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Integer

Status Register

Bit |

Name |

Description |

|---|---|---|

0 |

standby |

output is in standby |

1 |

live |

output is active |

2 |

nonhalt1 |

available |

3 |

nonhalt2 |

available |

4 |

overCurrTrip |

over current trip |

5 |

overVoltTrip |

over voltage trip |

6 |

overPwrTrip |

over power trip |

7 |

remoteSenseLoss |

remote sense voltage outside of acceptable bounds |

8 |

underVoltTrip |

under voltage trip |

9 |

shutdown |

target is creating a shutdown condition |

10 |

linPwrLim |

power across linear modules exceed ratings |

11 |

resPwrLim |

power across resistors exceed ratings |

12 |

bootFailure |

one or multiple target did not boot up |

13 |

bootState |

one or more targets are waiting to boot |

14 |

phaseCurr |

rated phase current exceeded |

15 |

comm |

communications are corrupted |

16 |

overCurrProtect |

terminal current exceeded product rating |

17 |

overVoltProtect |

terminal voltage exceeded product rating |

18 |

tempRLin |

linear module exceeded temperature |

19 |

blownFuse |

fuse is blown on the auxiliary power supply |

20 |

interlock |

interlock open |

21 |

haltUserClear |

available |

22 |

maintenance |

maintenance |

23 |

tempDMod |

diode modules exceeded temperature |

24 |

incompatibleSysConfig |

incompatible system configuration |

25 |

stackOverflow |

exceeded firmware stack |

26 |

lineFault |

line fault analog/digital inputs |

27 |

tempRMod |

resistor module exceeded temperature |

28 |

belowRatedMinVolt |

below minimum voltage rating(28) |

29 |

outOfRegulation |

out of regulation, unexpected currents measured |

30 |

targetUpgrade |

mainctrl upgrading other targets |

31 |

haltSelfClear |

available |

32 |

phaseLoss |

one or more phase missing |

33 |

blownFuseInput |

input fuse blown on fuse/emi filter |

34 |

fanLockedRotor |

one or more fan’s rotor has locked |

35 |

notUsed29 |

available |

36 |

tempPwrMod |

power processing module temperature fault |

37 |

tempOutputMod |

output filter module temperature fault |

38 |

tempOutputCap |

output capacitors temperature fault |

39 |

notUsed25 |

available |

40 |

notUsed26 |

available |

41 |

notUsed27 |

available |

42 |

notUsed28 |

available |

43 |

notUsed1 |

available |

44 |

notUsed2 |

available |

45 |

notUsed3 |

available |

46 |

notUsed4 |

available |

47 |

notUsed5 |

available |

48 |

invalidSysRating |

invalid system rating |

49 |

notUsed7 |

available |

50 |

notUsed8 |

available |

51 |

notUsed9 |

available |

52 |

notUsed10 |

available |

53 |

notUsed11 |

available |

54 |

notUsed12 |

available |

55 |

notUsed13 |

available |

56 |

notUsed14 |

available |

57 |

notUsed15 |

available |

58 |

notUsed16 |

available |

59 |

notUsed17 |

available |

60 |

notUsed18 |

available |

61 |

notUsed19 |

available |

62 |

notUsed20 |

available |

63 |

notUsed21 |

available |

11.4.1.3. Input¶

This command enables or disables the MagnaLOAD electronic load input. The state of a disabled input is a high impedance condition.

- Write Instance

17

- Supported Service

Set

- Register Count

1

- Data Format

Boolean

11.4.2. Measurement Commands¶

11.4.2.1. MeasCurrQ¶

This query commands the MagnaLOAD electronic load to measure and return the average current through the DC terminals.

- Write Instance

257

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.2.2. MeasVoltQ¶

This query commands commands the MagnaLOAD electronic load to measure and return the average voltage at the DC terminals. If the remote sense function is used and engaged, this command returns the voltage measured at the sense terminals.

- Write Instance

258

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.2.3. MeasPwrQ¶

This query commands commands the MagnaLOAD electronic load to measure and return the average power at the DC terminals.

- Write Instance

259

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.2.4. MeasResQ¶

This query commands commands the MagnaLOAD electronic load to measure and return the average power at the DC terminals.

- Write Instance

260

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.3. Setpoint Commands¶

11.4.3.1. SetpointCurr¶

This command programs the current set-point that the MagnaLOAD electronic load will regulate to when operating in constant current mode.

- Write Instance

513

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

514

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.3.2. SetpointVolt¶

This command programs the voltage set-point, in volts, which the MagnaLOAD electronic load will regulate to when operating in constant voltage mode.

- Write Instance

515

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

516

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.3.3. SetpointPwr¶

This command programs the power set-point, in watts, which the MagnaLOAD electronic load will regulate to when operating in constant power mode.

- Write Instance

517

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

518

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.3.4. SetpointRes¶

This command programs the resistance set-point, in ohms, which the MagnaLOAD electronic load will regulate to when operating in constant resistance mode.

- Write Instance

519

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

520

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.4. Trip Commands¶

11.4.4.1. OverTripCurr¶

This command programs the over current trip (OCT) set-point. If the input current exceeds the over current trip set-point for multiple samples, the input is disconnected and an OCT fault is indicated.

- Write Instance

769

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

770

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.4.2. OverTripVolt¶

This command programs the over voltage trip (OVT) set-point. If the input voltage exceeds the over voltage trip set-point for multiple samples, the input is disconnected and an OVT fault is indicated.

- Write Instance

771

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

772

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.4.3. OverTripPwr¶

This command programs the over power trip (OPT) set-point. If the input power exceeds the over power trip set-point for multiple sample, the input is disconnected and an OPT fault is indicated.

- Write Instance

773

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

774

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.4.4. UnderTripVolt¶

This command programs the under voltage trip (UVT) set-point. If the input voltage falls below the under voltage trip set-point for multiple samples, the input is disconnected and an UVT fault is indicated.

- Write Instance

775

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

776

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5. Slew Commands¶

11.4.5.1. RiseRampCurr¶

This command sets the current slew rate for increasing current transitions while in constant current regulation. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1025

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1026

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.2. RiseRampVolt¶

This command sets the voltage slew rate for increasing voltage transitions while in constant voltage regulation. The units for voltage slew rate are volts per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1027

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1028

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.3. RiseRampPwr¶

This command sets the power slew rate for increasing power transitions while in constant power regulation. The units for power slew rate are watts per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1029

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1030

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.4. RiseRampRes¶

This command sets the resistance slew rate for increasing resistance transitions while in constant resistance regulation. The units for resistance slew rate are ohms per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1031

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1032

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.5. FallRampCurr¶

This command sets the current slew rate for decreasing current transitions while in constant current regulation. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1033

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1034

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.6. FallRampVolt¶

This command sets the voltage slew rate for decreasing voltage transitions while in constant voltage regulation. The units for voltage slew rate are volts per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1035

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1036

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.7. FallRampPwr¶

This command sets the power slew rate for decreasing power transitions while in constant power regulation. The units for power slew rate are watts per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1037

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1038

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.5.8. FallRampRes¶

This command sets the resistance slew rate for decreasing resistance transitions while in constant resistance regulation. The units for resistance slew rate are ohms per millisecond. MAXimum sets the slew to the fastest possible rate. MINimum sets the slew to the slowest rate. Slew rates less than the minimum value are set to MINimum. Slew rate settings less than the minimum value are set to MINimum. Slew rate settings greater than the maximum value are set to MAXimum.

- Write Instance

1039

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1040

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.6. Control Commands¶

11.4.6.1. PowerRange¶

This command activates a programmable series resistance and is available only in ARx and WRx models. When enabled, power dissipation is shared across series resistors and linear devices allowing the product to reach higher power levels.

- Write Instance

1281

- Supported Service

Set

- Register Count

1

- Data Format

Boolean

- Read Instance

1282

- Supported Service

Get

- Register Count

1

- Data Format

Boolean

11.4.6.2. ControlMode¶

This command configures the MagnaLOAD electronic load’s control mode. Control Modes provides more information about the various options.

- Write Instance

1283

- Supported Service

Set

- Register Count

1

- Data Format

16-bit Integer

- Read Instance

1284

- Supported Service

Get

- Register Count

1

- Data Format

16-bit Integer

11.4.7. Function Generator Commands¶

11.4.7.1. FuncType¶

This command selects the desired function for the integrated function generator, which is active when the product’s set point source is set to function generator.

- Write Instance

1537

- Supported Service

Set

- Register Count

1

- Data Format

16-bit Integer

- Read Instance

1538

- Supported Service

Get

- Register Count

1

- Data Format

16-bit Integer

11.4.7.2. FuncSinAmpl¶

This command sets the amplitude (Adc) for the sinusoid function when the set point source is set to 1 (function generator) and the function type is set to 0 (sinusoid).

- Write Instance

1539

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1540

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.3. FuncSinOff¶

This command sets the DC offset from zero (Adc) for the sinusoid function midline when the set point source is set to 1 (function generator) and the function type is set to 0 (sinusoid).

- Write Instance

1541

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1542

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.4. FuncSinPrd¶

This command sets the period (milliseconds) for the sinusoid function when the set point source is set to 1 (function generator) and the function type is set to 0 (sinusoid). The sinusoid’s period is the length of one full cycle.

- Write Instance

1543

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1544

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.5. FuncSquLoLevel¶

This command sets the low level amplitude for the square function when the set point source is set to 1 (function generator) and the function type is set to 1 (square).

- Write Instance

1545

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1546

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.6. FuncSquHiLevel¶

This command sets the high level amplitude for the square function when the set point source is set to 1 (function generator) and the function type is set to 1 (square).

- Write Instance

1547

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1548

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.7. FuncSquLoPrd¶

This command sets the period/duration (milliseconds) that the square function remains at the low level amplituide when the set point source is set to 1 (function generator) and the function type is set to 1 (square).

- Write Instance

1549

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1550

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.8. FuncSquHiPrd¶

This command sets the period/duration (milliseconds) that the square function remains at the low level amplituide when the set point source is set to 1 (function generator) and the function type is set to 1 (square).

- Write Instance

1551

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1552

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.9. FuncStepLoLevel¶

This command sets the low level amplitude for the step function when the set point source is set to 1 (function generator) and the function type is set to 2 (step).

- Write Instance

1553

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1554

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.10. FuncStepHiLevel¶

This command sets the high level amplitude for the step function when the set point source is set to 1 (function generator) and the function type is set to 2 (step).

- Write Instance

1555

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1556

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.11. FuncRampLoLevel¶

This command sets the low level amplitude for the ramp function when the set point source is set to 1 (function generator) and the function type is set to 3 (ramp).

- Write Instance

1557

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1558

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.12. FuncRampHiLevel¶

This command sets the high level amplitude for the ramp function when the set point source is set to 1 (function generator) and the function type is set to 3 (ramp).

- Write Instance

1559

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1560

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.13. FuncRampRisePrd¶

This command sets the period/duration (milliseconds) for the ramp function to transition from the low level amplitude to the high level amplitude when the set point source is set to 1 (function generator) and the function type is set to 3 (ramp).

- Write Instance

1561

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1562

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.7.14. FuncRampFallPrd¶

This command sets the period/duration (milliseconds) for the ramp function to transition from the high level amplitude to the low level amplitude when the set point source is set to 1 (function generator) and the function type is set to 3 (ramp).

- Write Instance

1563

- Supported Service

Set

- Register Count

1

- Data Format

32-bit Floating Point Number

- Read Instance

1564

- Supported Service

Get

- Register Count

1

- Data Format

32-bit Floating Point Number

11.4.8. Configuration Commands¶

11.4.8.1. FactoryRestore¶

This command performs a factory restore to default EPROM values. Both Soft Restore and Hard Restore are available through command parameters.

- Write Instance

1793

- Supported Service

Set

- Register Count

1

- Data Format

16-bit Integer

11.4.8.2. Lock¶

This command configures the MagnaLOAD electronic load’s lock state. While locked, the stop button is the only functional button on the front panel. See Lock for more details on how lock works and how behaves relative to other locking inputs (front panel and digital input).

- Write Instance

1795

- Supported Service

Set

- Register Count

1

- Data Format

Boolean

- Read Instance

1794

- Supported Service

Get

- Register Count

1

- Data Format

Boolean

11.4.8.3. SenseMode¶

This command configures where the MagnaLOAD electronic load senses voltage. The sense location also effects how power and resistance are calculated. Local sensing monitors the directly across the output terminals. Remote sensing, as described in Remote Sense Connection, measures across the terminal JS2. This external connection can be used to improve regulation at the point of load, as is needed for example, in compensating voltage drops caused by wire resistance.

- Write Instance

1798

- Supported Service

Set

- Register Count

1

- Data Format

16-bit Integer

- Read Instance

1799

- Supported Service

Get

- Register Count

1

- Data Format

16-bit Integer

11.4.8.4. SetSource¶

The command selects and routes different set points sources to the digital controller. Operation of this feature is described in Set Point Source. By default, the source is set to local (value 0), where set points originating from the front panel or communication interfaces are routed to the ALx Series digital control. When the source is set to function generator (value 1), set points are generated internally, by a periodic function generator block. When external analog input (value 3) is set, the voltage(s) applied to the rear connector are converted into set points.

- Write Instance

1802

- Supported Service

Set

- Register Count

1

- Data Format

16-bit Integer

- Read Instance

1803

- Supported Service

Get

- Register Count

1

- Data Format

16-bit Integer