High Current Power Supply for Reinforced Carbon–Carbon Production

Magna-Power manufactured two 250 kW, 6,000 Adc programmable DC power supplies in a furnace heating application for space-grade material production.

Magna-Power recently delivered two 250 kW, 6000 Adc power supplies from Magna-Power’s MT Series (Model MTD40-6000/380+LXI) to the Indian Space Research Organization (ISRO). The power supplies will used in a furnace heater application in the manufacture of reinforced carbon–carbon; a process patented process by ISRO. Reinforced carbon–carbon is a composite of carbon fiber reinforced in graphite with high thermal shock resistance, originally developed for space reentry vehicles. The two MT Series power supplies were sold by Magna-Power's distributor in India, Scientific Mes Technik Pvt. Ltd.

The highest current offering in Magna-Power’s high-power MT Series programmable DC power supplies is the 6000 Adc 250 kW model. The MT Series offers 150 kW and 250 kW models from a single output, not multiple products paralleled together. This single output stage means the internal output rectifier/filtering bus work after the high-frequency transformer must be rated for the full current of the supply. Multiple high-current units can be combined in master-slave parallel to achieve even higher currents.

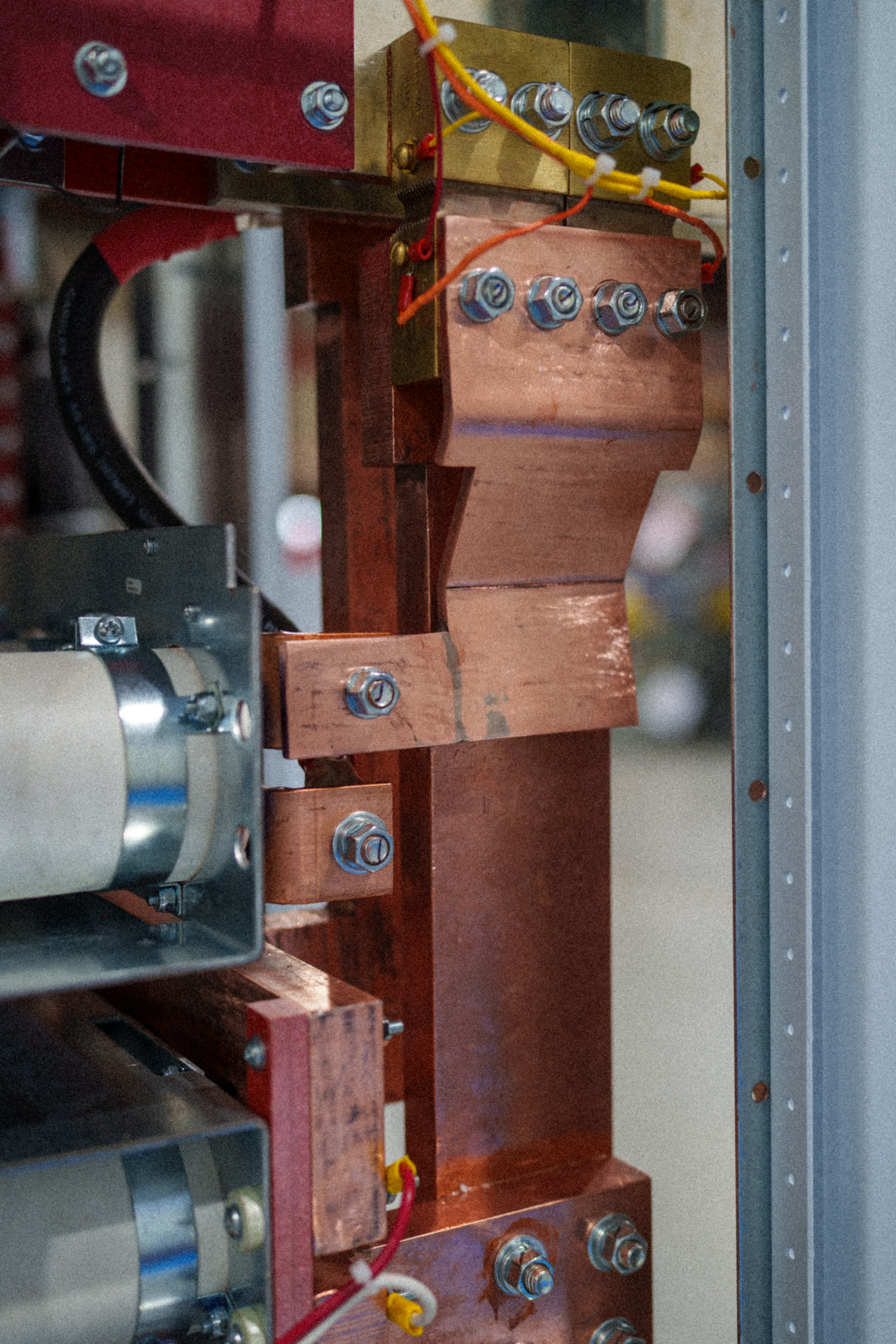

For the very high current MT Series units, much of the output copper buswork is machined-to-order, allowing exact measurements to be taken prior to fabrication. Various operations internal to Magna-Power support the fabrication of this bus work, including machining, brazing, and press brake operations. Fortunately, we were able to grab a few shots with the rear panels removed at our factory in New Jersey before shipping the highest current offering, showing some of the quality workmanship by the Magna-Power's team.