Série MT

Programmable DC Power Supply

Magna-Power Electronics MT Series uses the same reliable current-fed power processing technology and controls as the rest of the MagnaDC programmable power supply product line, but with larger high-power modules: individual 150 kW and 250 kW power supplies. The high-frequency IGBT-based MT Series units are among the largest standard switched-mode power supplies on the market, minimizing the number of switching components when comparing to smaller module sizes. Scaling in the multi-megawatts is accomplished using the UID47 device, which provides master-slave control: one power supply takes command over the remaining units, for true system operation. As an added safety measure, all MT Series units include an input AC breaker rated for full power.

250 kW modules come standard with an embedded 12-pulse harmonic neutralizer, ensuring low total harmonic distortion (THD). Even higher quality AC waveforms are available with an external additional 500 kW 24-pulse or 1000 kW 48-pulse harmonic neutralizers, designed and manufactured exclusively by Magna-Power for its MT Series products.

Build-Time: 10-14 Weeks

Current-Fed Topology: Robust Power Conversion

All MagnaDC programmable DC power supplies utilize high-frequency IGBT-based power processing in current-fed topology. This topology adds an additional stage over the conventional voltage-fed topology for enhanced control and system protection, ensuring that even under a fault condition, the power supply will self-protect. Due to the self-protecting characteristics of this topology, the possibility of fast rising current spikes and magnetic core saturation is eliminated.

Made in the USA, Available Worldwide

For complete control of quality, MagnaDC programmable DC power supplies are designed and manufactured at Magna-Power's vertically integrated USA manufacturing facility in Flemington, New Jersey. Heat-sinks and various metal assemblies are machined from aluminum. Sheet metal is cut, punched, sanded, bent, and powder coated in-house. Magnetics are wound-to-order from validated designs based on a model's voltage and current. A full surface mount technology (SMT) with multiple stages of 3D automated optical inspection ensure high-quality board assemblies. Finally after assembly, products undergo comprehensive test and calibration, followed by an extended burn-in period.

Standard Safety Features

MagnaDC programmable DC power supplies have extensive diagnostic functions, including:

- AC Phase Loss

- Excessive Thermal Conditions

- Over Voltage Trip (Programmable)

- Over Current Trip (Programmable)

- Cleared Fuse

- Excessive Program Line Voltage

- Interlock Fault

When in standby or diagnostic fault, the AC mains are mechanically disconnected by an embedded AC contactor, providing confidence that the unit is only processing power when desired.

Finally, with a dedicated +5V interlock input pin and included +5V reference on all models, external emergency stop systems can be easily integrated using an external contact.

Limitless Programming Capabilities

With support for Standard Commands for Programmable Instrumentation (SCPI), MagnaDC power supplies provide an easy to use API with ASCII commands in readable text. Over 40 commands allow programmatic access to product registers, starting and stopping the product, control of voltage and current, high-accuracy measurement queries, and product configuration. Simple scripting or complex software can be achieved, with extensive documentation and examples provided by Magna-Power.

MagnaDC power supplies include RS232 communication interface standard with optional LXI TCP/IP Ethernet (+LXI) and IEEE-488 GPIB (+GPIB) options.

External User I/O for Analog and PLC Control

Using the standard rear isolated 37-pin user I/O connector, the MagnaDC programmable power supplies can be completely controlled and monitored using external signals. The voltage, current, over voltage and over current set points can be set by applying a 0-10V analog signal. Remote start, stop, clear and interlock (emergency stop tie-in) are controlled by applying a 5V digital signal. Each diagnostic condition is given a designated pin, which reads +5V when high. Reference +5V and +10V signals are provided, eliminating the need for external voltage signals and allowing the use of dry contacts.

All communications and user I/IO pins are isolated from the output terminals and referenced to earth-ground as standard.

High Performance Master-Slave Operation

All MagnaDC programmable DC power supplies come with master-slaving capability.

The MagnaDC master-slaving strategy helps to ensures no degradation in performance as units are added in parallel or series by providing gate drive signals directly from the master to the slave units. This strategy ensures one control loop for the system and eliminates the noise susceptibility commonly found when sending analog control references over long distances.

The Universal Interface Device 47 (UID47) accessory eases master-slave parallel or series configuration of Magna-Power DC power supplies, enabling near equal current or voltage sharing, depending on the configuration.

Master-slave series operation is supported to combined voltages up to the product's DC Output Isolation specification. No external blocking diodes are requires for series operation.

Magna-Power Software, NI LabVIEW Drivers, and IVI Drivers

All MagnaDC power supplies come standard with an IVI driver and an NI LabVIEW driver featuring a full set of VIs. Get started quickly with either driver using included example programs.

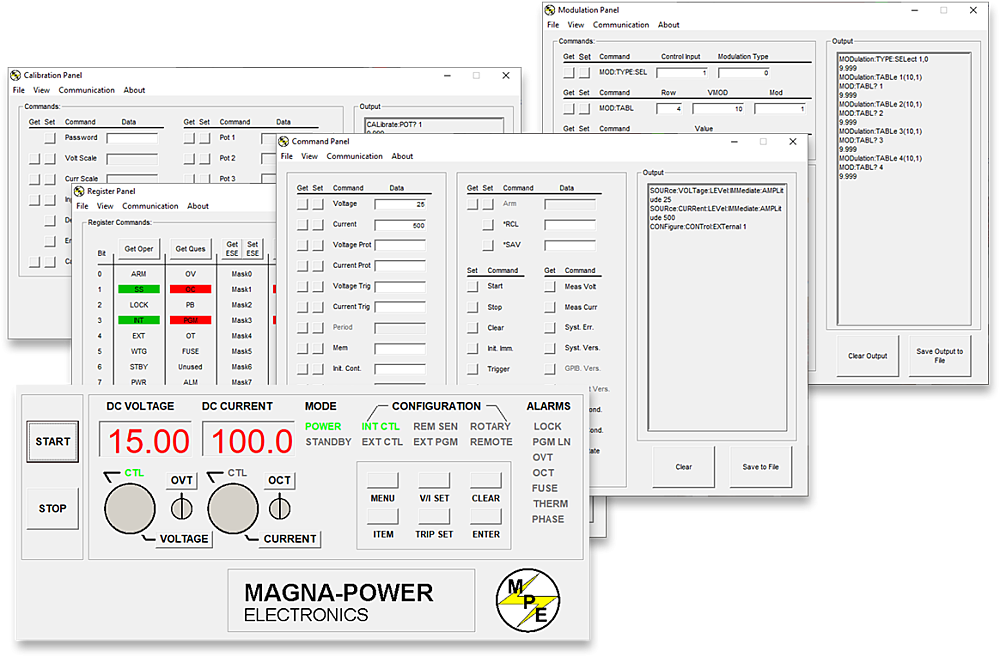

Magna-Power's included Remote Interface Software (pictured) provides an easy and intuitive method to operate a Magna-Power Electronics power supply with computer control. The software includes a virtual control panel, command panel to explore available commands, register panel to monitor the power supply status, calibration panel for recalibrating internal digital potentiometers, firmware panel for upgrading firmware, and a finally a modulation panel to emulate non-linear profiles.

All communication interfaces are supported across the various methods to program MagnaDC power supplies.

MT Series Harmonic Neutralization

Magna-Power's Harmonic Neutralizers eliminate families of harmonic components by multiplying the number of input phases with specially wound magnetic components, reducing the total harmonic distortion (THD). These magnetic components, in combination with equally loaded, high-power DC power supplies, offer a cost-effective solution to maintaining power quality at acceptable levels, enabling applications to benefit from Magna-Power's reliable high-frequency switch-mode power supplies, extended into multi-megawatts. A 12-pulse Harmonic Neutralizer is embedded in all 250 kW models and its installation is transparent to the end user. For applications demanding an even better THD level than that provided by a 12-pulse waveform, external 24-pulse and 48-pulse harmonic neutralizers are available from Magna-Power. Contact you local sales partner for more information.

Understanding AC Harmonic Waveforms

The following figures are representative of expected AC current waveforms for the various pulses available from Magna-Power Electronics power supplies. Standard models 1.5 kW through 150 kW produce 6-pulse waveforms, while 250 kW models produce 12-pulse waveforms. Magna-Power Electronics Harmonic Neutralizers suppress families of harmonics by increasing the number of power phases. It can be used when multiple power supplies are used in series or parallel and are equally loaded. Harmonic Neutralizers can produce 12-pulse, 18-pulse, 24-pulse, or 48-pulse waveforms which have harmonic current components on the order of 12n±1, 18n±1, 24n±1, or 48n±1, respectively. The following figures show the theoretical difference for waveforms with a different number of pulses. Harmonic Neutralizers are protected with appropriate sized primary-side circuit breakers.

Why Neutralize Harmonics?

Input current harmonics are a by-product of nearly all power supplies. Power can only be delivered to the load if the frequency and phase of the voltage and current match. For a three phase power supply using a three phase input rectifier, the input current has a theoretical spectrum of 6n±1 where n is an integer incrementing from 1; this is known as a 6-pulse waveform. This means that a power supply with a three phase input rectifier will produce input currents at 1, 5, 7, 11, 13, 17, 19 ... times the fundamental frequency. The theoretical magnitude decays as the reciprocal of the harmonic component. The 5th and 7th harmonic components have magnitudes of 20% and 14% of the fundamental component, respectively. Harmonics currents in power systems can find unusual paths and can cause problems if the magnitude is significant and there are loads sensitive to harmonic frequencies. For example, lighting ballasts have series connected capacitors and inductors which can be excited by harmonic currents. IEEE has introduced standard, IEEE 519, which defines recommended limits. Implementing this standard requires a knowledge of the power system and other loads producing harmonics. Unfortunately, the standard can allow the same power supply to possibly exceed limits in one application and not in another. In the same respect, a power supply may or may not can cause a harmonic related problem with or without meeting IEEE 519. The best solution to minimize the risk of a harmonic problem is to eliminate the harmonic current at the source.

Front Panel - Standard

Front Panel - C Version

REM SEN: Remote sense enabled

INT CTL: Front panel start/stop/clear enabled

EXT CTL: External start/stop/clear enabled

ROTARY: Front panel rotary knob input

EXT PGM: External analog voltage-current control

REMOTE: Computer control

LOC: Interlock

PGL: External input voltage beyond limits

PHL: Under-voltage AC input

THL: Over-temperature condition

OVT: Over-voltage protection has tripped

OCT: Over-current protection has tripped

MENU: Selects function

ITEM: Selects item within function

V/I DIS: Displays voltage-current settings

TRIP DIS: Displays OVT and OCT setting

CLEAR: Clears settings or resets fault

ENTER: Select item

Model Ordering Guide

For both ordering and production, MT Series models are uniquely defined by several key characteristics, as defined by the following diagram:

MT Series Models

There are 49 different models in the MT Series spanning power levels: 150 kW, 250 kW, 500 kW, 750 kW, 1000 kW+. To determine the appropriate model:

- Select the desired Max Voltage (Vdc) from the left-most column.

- Select the desired Max Current (Adc) from the same row that contains your desired Max Voltage.

- Construct your model number according to the model ordering guide.

| 150 kW | 250 kW | 500 kW* | 750 kW* | 1000 kW* | |||

|---|---|---|---|---|---|---|---|

| Max Voltage (Vdc) | Max Current (Adc) | Ripple (mVrms) | Efficiency | ||||

| 32 | 4500 | N/A | N/A | N/A | N/A | 40 | 90% |

| 40 | 3750 | 6000 | 12000 | 18000 | 24000 | 40 | 91% |

| 50 | 3000 | 5000 | 10000 | 15000 | 20000 | 50 | 91% |

| 60 | 2500 | 4160 | 8320 | 12480 | 16640 | 60 | 91% |

| 80 | 1850 | 3000 | 6000 | 9000 | 12000 | 60 | 91% |

| 100 | 1500 | 2500 | 5000 | 7500 | 10000 | 60 | 91% |

| 125 | 1200 | 2000 | 4000 | 6000 | 8000 | 100 | 91% |

| 160 | 900 | 1500 | 3000 | 4500 | 6000 | 120 | 91% |

| 200 | 750 | 1250 | 2500 | 3750 | 5000 | 125 | 91% |

| 250 | 600 | 1000 | 2000 | 3000 | 4000 | 130 | 92% |

| 300 | 500 | 833 | 1666 | 2499 | 3332 | 160 | 92% |

| 375 | 400 | 660 | 1320 | 1980 | 2640 | 170 | 92% |

| 400 | 375 | 625 | 1250 | 1875 | 2500 | 180 | 92% |

| 500 | 300 | 500 | 1000 | 1500 | 2000 | 220 | 92% |

| 600 | 240 | 400 | 800 | 1200 | 1600 | 250 | 92% |

| 800 | 180 | 300 | 600 | 900 | 1200 | 300 | 92% |

| 1000 | 150 | 250 | 500 | 750 | 1000 | 400 | 92% |

| 1250 | 120 | 200 | 400 | 600 | 800 | 500 | 92% |

| 1600 | 90 | 150 | 300 | 450 | 600 | 600 | 92% |

| 2000 | 75 | 125 | 250 | 375 | 500 | 800 | 92% |

| 2500 | 60 | 100 | 200 | 300 | 400 | 900 | 92% |

| 3000 | 50 | 80 | 160 | 240 | 320 | 1000 | 92% |

| 4000 | 36 | 60 | 120 | 180 | 240 | 1100 | 92% |

| 5000 | 30 | 50 | 100 | 150 | 200 | 92% | |

| 6000 | 25 | 41.6 | 83.2 | 124.8 | 166.4 | 92% | |

| AC Input Voltage (Vac) | Input Current Per Phase (Aac) | ||||||

| 380/415 Vac, 3Φ | 276 | 440 | 880 | 1320 | 1760 | ||

| 440/480 Vac, 3Φ | 238 | 380 | 760 | 1140 | 1520 | ||

* Power levels marked with an asterisk are achieved through master-slave parallel of 250 kW models. Contact sales for more information or to inquire for systems as large as 4,000 kW+.

Specifications

The following specifications are subject to change without notice. Unless otherwise noted, all specifications measured at the product's maximum ratings.

| Specification | Value |

|---|---|

3Φ AC Input Voltage

Available on all models |

380/400 Vac (operating range 342 to 440 Vac) 415 Vac (operating range 373 to 456 Vac) 440 Vac (operating range 396 to 484 Vac) 480 Vac (operating range 432 to 528 Vac) |

Input Frequency

|

50 Hz to 60 Hz |

Power Factor

|

> 0.92 at maximum power, 100 kW and 150 kW models > 0.96 at maximum power, 250 kW models |

AC Input Isolation

|

±2500 Vdc, maximum input voltage to ground |

| Specification | Value |

|---|---|

Voltage Ripple

|

Model specific. Refer to chart of available models. |

Line Regulation

Line regulation is a measure of a power supply's ability to maintain its output voltage (or current) given changes in the input line voltage. Line regulation is expressed as percent of change in the output voltage (or current) relative to the change in the input line voltage.

|

Voltage mode: ± 0.004% of full scale Current mode: ± 0.02% of full scale |

Load Regulation

Load regulation is a measure of the power supply's ability to maintain its output voltage (or current) given changes in the load, measured while operating at the maximum rated voltage (or current). Load regulation is expressed as the difference between voltage (or current) at full load minus voltage (or current) at min load, divided by the products max voltage (or current) rating.

|

Voltage mode: ± 0.01% of full scale Current mode: ± 0.04% of full scale |

Stability

|

± 0.10% for 8 hrs. after 30 min. warm-up |

Efficiency

|

90% to 92% Model specific. Refer to chart of available models. |

Maximum Slew Rate

Standard Models |

< 170 ms for a programmed output voltage change from 0 to 63% < 200 ms for a programmed output current change from 0 to 63% |

Maximum Slew Rate

Models with High Slew Rate Output (+HS) Option |

< 5 ms for a programmed output voltage change from 0 to 63% < 10 ms for a programmed output current change from 0 to 63% |

Bandwidth

Standard Models |

3 Hz with remote analog voltage programming 2 Hz with remote analog current programming |

Bandwidth

Models with High Slew Rate Output (+HS) Option |

60 Hz with remote analog voltage programming 45 Hz with remote analog current programming |

DC Output Isolation

Models Rated ≤1000 Vdc |

±1000 Vdc, maximum output voltage to ground |

DC Output Isolation

Models Rated >1000 Vdc or Models with +ISO Option |

±6000 Vdc, maximum output voltage to ground |

| Specification | Value |

|---|---|

Front Panel Programming

|

Stepless aluminum rotary knobs and keypad |

Computer Interface

|

RS232, D-sub DB-9, female (Standard) LXI TCP/IP Ethernet RJ45 (Option +LXI) IEEE-488 GPIB (Option +GPIB) |

External User I/O Port

|

37-pin D-sub DB-37, female Referenced to Earth ground; isolated from power supply output See User Manual for pin layout |

Remote Sense Limits (Wired)

Available for models ≤ 1000 Vdc without High Isolation Output (+ISO) option |

3% maximum voltage drop from output to load |

| Specification | Value |

|---|---|

Voltage Programming Accuracy

Programming accuracy is a measure of how close the actual power supply output will be to the programmed setting, as measured by an ideal meter.

|

± 0.075% of max rated voltage |

Over Voltage Trip Programming Accuracy

|

± 0.075% of max rated voltage |

Current Programming Accuracy

Programming accuracy is a measure of how close the actual power supply output will be to the programmed setting, as measured by an ideal meter.

|

± 0.075% of max rated current |

Over Current Trip Programming Accuracy

|

± 0.075% of max rated current |

Voltage Readback Accuracy

Readback accuracy is a measure of how close the measured and displayed value will be to the actual power supply output.

|

± 0.2% of max rated voltage |

Current Readback Accuracy

Readback accuracy is a measure of how close the measured and displayed value will be to the actual power supply output.

|

± 0.2% of max rated current |

| Specification | Value |

|---|---|

Analog Programming and Monitoring Levels

|

0-10 Vdc |

Analog Output Impedances

|

Voltage output monitoring: 100 Ω Current output monitoring: 100 Ω +10V reference: 1 Ω |

Digital Programming and Monitoring Limits

|

Input: 0 to 5 Vdc, 10 kΩ input impedance Output: 0 to 5 Vdc, 5 mA drive capacity |

| Specification | Value |

|---|---|

Size and Weight

100 kW Models |

Floor-standing double-bay 19" cabinet with casters 67" H x 48" W x 31.5" D (170.2 x 121.9 x 80.0 cm) 1600 lbs (725.8 kg) |

Size and Weight

150 kW Models |

Floor-standing double-bay 19" cabinet with casters 67" H x 48" W x 31.5" D (170.2 x 121.9 x 80.0 cm) 2100 lbs (952.5 kg) |

Size and Weight

250 kW Models |

Floor-standing triple-bay 19" cabinet with casters 67" H x 72" W x 31.5" D (170.2 x 182.9 x 80.0 cm) 3300 lbs (1496.9 kg) |

| Specification | Value |

|---|---|

Ambient Operating Temperature

|

0°C to 50°C |

Storage Temperature

|

-25°C to +85°C |

Humidity

|

Relative humidity up to 95% non-condensing |

Temperature Coefficient

|

0.04%/°C of maximum output voltage 0.06%/°C of maximum output current |

Air Flow

|

Front and rear inlet, top exhaust |

| Specification | Value |

|---|---|

EMC

|

Complies with 2014/30/EU (EMC Directive) CISPR 22 / EN 55022 Class A |

Safety

|

Complies with EN61010-1 and 2014/35/EU (Low Voltage Directive) |

CE Mark

|

Yes |

RoHS Compliant

|

Yes |

Dimensional Diagrams

The following are vectorized diagrams for the MT Series. Refer to the Downloads section for downloadable drawings.

Options and Accessories

The following are options and accessories developed specifically for Magna-Power's MT Series

Accessories

External accessories and integration services are available for Magna-Power products

BDx Module

1U blocking diode module covering a wide range of voltages and currents and providing necessary cooling, power supply controls interface, and remote sensing location.

DBx Module

High-performance add-on bringing ultra-high stability less than 10 ppm, up to 24-bit resolution, and up to 10x reduction in ripple.

DC Power Cables

DC power cables with wide range voltage ratings, current ratings, and termination options, made-to-order by Magna-Power

UID47: Universal Interface Device 47

Master-slave interface device for load sharing. Includes interface device and (2) D-Sub 37-pin cables with a braided shield.

Additional Accessories

RS485 Converter

Industrial RS232 to Addressable RS485 Converter. Plugs into product's RS232 port.

UID46: Universal Interface Device 46

Master-slave interface device for load sharing. Includes interface device and (2) D-Sub 37 cables.

USB Edgeport Converter

Industrial Plug and Play USB to RS232 Converter. Adapter plugs into product's RS232 port.

Integrated Options

Standard integrated options are available for Magna-Power products, allowing the product's performance and communication interfaces to be tailors to the specific application.

High Isolation Output

Option Code: +ISO

Availability:

Available for models rated for 250 Vdc to 1000 Vdc, the +ISO option greatly increases the output isolation, used when the application demands floating or tying units in series beyond the standard ±1000 Vdc output isolation rating.

High Slew Rate Output

Option Code: +HS

Availability:

A hardware and control modification that replaces the standard output stage with one of low capacitance film and/or high RMS current rated aluminum electrolytic capacitors. This option provides higher bandwidth with faster output rise and fall times.

IEEE-488 GPIB

Option Code: +GPIB

Availability:

IEEE-488 General Purpose Interface Bus (GPIB) communication interface providing full command support and compatibility with other GPIB devices

Integrated Blocking Diode

Option Code: +BD

Availability:

An internally heatsinked protection diode on the positive output terminal of a MagnaDC programmable DC power supply to protect the product's output from reverse voltages far exceeding the product's output voltage rating.

LXI TCP/IP Ethernet

Option Code: +LXI

Availability:

TCP/IP Ethernet communication protocol and single RJ-45 interface, certified to the LXI Class C standard, for socket communications using conventional computer networks

Downloads

The following downloads are for the Série MT: