Serie ALx

DC Electronic Load

The ALx Series MagnaLOAD utilizes conventional linear MOSFET-based dissipative elements, allowing the series to achieve a very wide voltage-current operating range within the model’s maximum power rating. Using the same heat management innovations developed for Magna-Power’s high density programmable DC power supplies, the ALx Series’ conservative cooling ensures long product life with continuous full power operation in environments up to 50°C ambient operating temperature.

Build-Time: 10-14 Weeks

MagnaLINK™ Distributed Digital Control

Magna-Power’s MagnaLINK™ technology provides distributed Texas Instrument DSP control across power processing stages inside the MagnaLOAD DC electronic load. This technology follows a significant internal development cycle from Magna-Power to provide a unified digital control platform across its electronic loads and power supplies, featuring fully digital control loops, adjustable control gains, programmable slew rates, digital master-slaving, and many new advanced control technologies.

All ARx Series MagnaLOADs come with the following interfaces:

- Front panel knob, keypad, and menu system

- 25-pin configurable external user I/O, including a high-speed analog input

- Front and rear USB and rear RS-485 or optional Ethernet and IEEE-4888 GPIB

When in standby or diagnostic fault, the DC input bus is disconnected via a switching device.

Finally, with a dedicated +5V interlock input pin and included +5V reference on all models, external emergency stop systems can be easily integrated using an external contact.

Five Operating Modes

To accommodate a variety of DC sources, all ARx Series MagnaLOADs come with many configurable control modes, including:

- Voltage Mode

- Current Mode

- Power Mode

- Resistance Mode

- Shunt Regulator Mode

Preference for DC regulation is given to the parameter in the selected mode within the programmed set-points. Using the MagnaLOAD's set-points and trip settings, the product can configured to either trip with a fault when a limit is exceeded or to cross-over into a different regulation state.

Shunt Regulator Mode turns the MagnaLOAD into a high-speed smart braking resistor, engaging the DC input only when a specified voltage and exceeded by a user-defined percentage, while limiting the shunt current to a programmed set-point.

Configurable External User I/O

Beyond the front panel and computer controls, all MagnaLOADs come standard with a 25-pin D-Sub connector designated as the External User I/O. This connector provides:

- 8 Digital Outputs

- 4 Digital Inputs

- 4 Analog Outputs

- 4 Analog Inputs

All the analog-digital I/O ports are configurable, allowing the user to select which parameters they want to control and monitor. This configurable I/O scheme reduces complexity, eases PLC integrationand allows control parameters from various interfaces simultaneously.

The MagnaLOAD's configurable analog inputs provide 0-10V programming from PLCs and external D/A converters.

Digital Master-Slaving: Expandibility Without Compromise

All MagnaLOADs come standard with a MagnaLINK™ Input and a MagnaLINK™ Output port, which provides plug and play digital master-slaving. Simply connect the master's MagnaLINK™ Output to the slave's MagnaLINK™ Input and, using the MagnaWEB software, the products will automatically configure themselves for master-slave operation as a higher-power unit based on the populated ports. Buffered digital MagnaLINK™ connections means many MagnaLOADs can be daisy-chained in master-slave operation. Master-slave MagnaLOAD units will aggregate measurements to one display panel.

The internal MagnaLINK™ protocol was developed with expandability at the forefront. When configured for master-slave operation, the master controller takes control of all the slave's digital "targets." With this digital master-slaving strategy, it is completely transparent whether the unit is operating as a stand-alone product or in master-slave.

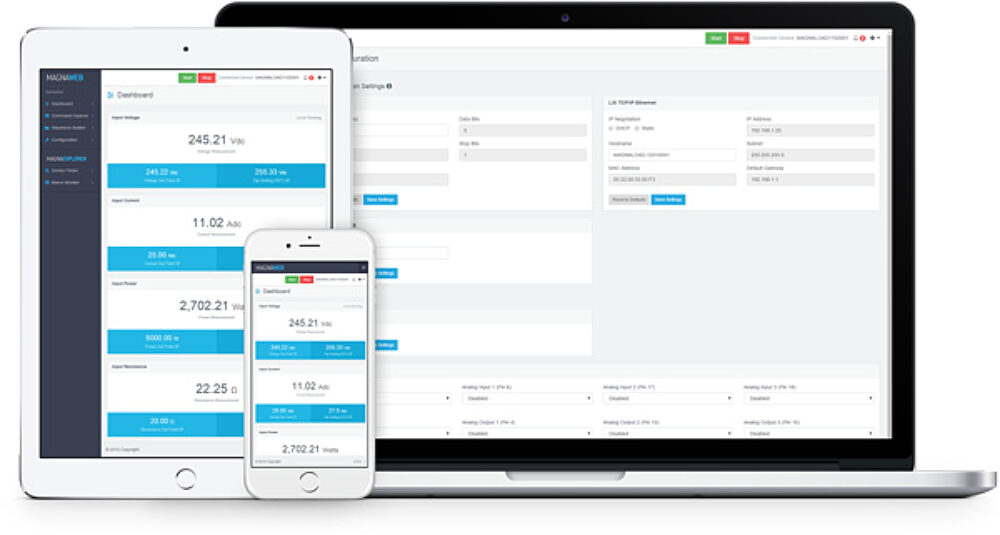

MagnaWEB Software Interface

Magna-Power's next generation software interface, MagnaWEB, provides intuitive and user-friendly web-browser based controls for programming and measurement read-back of the MagnaLOAD's activity. Virtually all of the MagnaLOAD's available functions can be controlled and monitored from the MagnaWEB software over any of product's installed communication interfaces.

MagnaWEB uses a server-client software model to provide access to the MagnaLOAD from nearly any device and operating system. Install and run the MagnaWEB software locally on Windows then, using a web browser, access the server connected to the MagnaLOAD from a variety of devices including other desktops, tablets or smart-phones.

Front Panel - Standard

Front Panel - Blank Panel (+BP) Option

STOP: Disables the DC input bus

BACK: Moves back one level in the menu

ENTER: Selects the highlighted menu item

CLEAR: Removes the product from a faulted state

LOCK: Locks the front panel, with password protection available

Model Ordering Guide

Model Ordering Guide

There are 27 different models in the ALx Series spanning power levels: 1.25 kW, 2.5 kW, 5 kW, 7.5 kW, 10 kW, 12.5 kW, 15 kW, 17.5 kW, 20 kW.

Use the following ordering guide and models chart to define the best model for your application.

ALx Series Models

There are 27 different models in the ALx Series spanning power levels: 1.25 kW, 2.5 kW, 5 kW, 7.5 kW, 10 kW, 12.5 kW, 15 kW, 17.5 kW, 20 kW. To determine the appropriate model:

- Select the desired Max Voltage (Vdc) from the left-most column.

- Select the desired Max Current (Adc) from the same row that contains your desired Max Voltage.

- Construct your model number according to the model ordering guide.

| Model | Maximum Power | Maximum Voltage | Maximum Current | Package Type | Minimum Voltage |

|---|---|---|---|---|---|

| ALx1.25-200-300 | 1.25 kW | 200 Vdc | 300 Adc | Rack-mount | 2.5 Vdc |

| ALx1.25-500-125 | 1.25 kW | 500 Vdc | 125 Adc | Rack-mount | 6.0 Vdc |

| ALx1.25-1000-37.5 | 1.25 kW | 1000 Vdc | 37.5 Adc | Rack-mount | 7.5 Vdc |

| ALx2.5-200-600 | 2.5 kW | 200 Vdc | 600 Adc | Rack-mount | 2.5 Vdc |

| ALx2.5-500-250 | 2.5 kW | 500 Vdc | 250 Adc | Rack-mount | 6.0 Vdc |

| ALx2.5-1000-75 | 2.5 kW | 1000 Vdc | 75 Adc | Rack-mount | 7.5 Vdc |

| ALx5-200-1200 | 5 kW | 200 Vdc | 1200 Adc | Floor-standing | 2.5 Vdc |

| ALx5-500-500 | 5 kW | 500 Vdc | 500 Adc | Floor-standing | 6.0 Vdc |

| ALx5-1000-150 | 5 kW | 1000 Vdc | 150 Adc | Floor-standing | 7.5 Vdc |

| ALx7.5-200-1800 | 7.5 kW | 200 Vdc | 1800 Adc | Floor-standing | 2.5 Vdc |

| ALx7.5-500-750 | 7.5 kW | 500 Vdc | 750 Adc | Floor-standing | 6.0 Vdc |

| ALx7.5-1000-225 | 7.5 kW | 1000 Vdc | 225 Adc | Floor-standing | 7.5 Vdc |

| ALx10-200-2400 | 10 kW | 200 Vdc | 2400 Adc | Floor-standing | 2.5 Vdc |

| ALx10-500-1000 | 10 kW | 500 Vdc | 1000 Adc | Floor-standing | 6.0 Vdc |

| ALx10-1000-300 | 10 kW | 1000 Vdc | 300 Adc | Floor-standing | 7.5 Vdc |

| ALx12.5-200-3000 | 12.5 kW | 200 Vdc | 3000 Adc | Floor-standing | 2.5 Vdc |

| ALx12.5-500-1250 | 12.5 kW | 500 Vdc | 1250 Adc | Floor-standing | 6.0 Vdc |

| ALx12.5-1000-375 | 12.5 kW | 1000 Vdc | 375 Adc | Floor-standing | 7.5 Vdc |

| ALx15-200-3600 | 15 kW | 200 Vdc | 3600 Adc | Floor-standing | 2.5 Vdc |

| ALx15-500-1500 | 15 kW | 500 Vdc | 1500 Adc | Floor-standing | 6.0 Vdc |

| ALx15-1000-450 | 15 kW | 1000 Vdc | 450 Adc | Floor-standing | 7.5 Vdc |

| ALx17.5-200-4200 | 17.5 kW | 200 Vdc | 4200 Adc | Floor-standing | 2.5 Vdc |

| ALx17.5-500-1750 | 17.5 kW | 500 Vdc | 1750 Adc | Floor-standing | 6.0 Vdc |

| ALx17.5-1000-525 | 17.5 kW | 1000 Vdc | 525 Adc | Floor-standing | 7.5 Vdc |

| ALx20-200-4800 | 20 kW | 200 Vdc | 4800 Adc | Floor-standing | 2.5 Vdc |

| ALx20-500-2000 | 20 kW | 500 Vdc | 2000 Adc | Floor-standing | 6.0 Vdc |

| ALx20-1000-600 | 20 kW | 1000 Vdc | 600 Adc | Floor-standing | 7.5 Vdc |

Specifications

The following specifications are subject to change without notice. Unless otherwise noted, all specifications measured at the product's maximum ratings.

| Specification | Value |

|---|---|

AC Input Voltage

1Φ, 2-wire + ground |

100-240 Vac (UI: Universal Input); Available on 1.25 to 17.5 kW Models 200-240 Vac (UI2: Universal Input 2); Available on 20 kW Models |

AC Input Frequency

|

50-60 Hz |

AC Input Isolation

|

±1500 Vac, maximum input voltage to ground |

| Specification | Value |

|---|---|

Front Panel Programming

|

Aluminum rotary knob with encoder, keypad, or up-down arrow for single bit control |

Computer Interfaces

Standard |

USB Host (Front): Type B USB Host (Rear): Type B RS485 (Rear): RJ-45 MagnaLINK™: RJ-25 x 2 |

Computer Interfaces

|

LXI TCP/IP Ethernet (Rear): RJ-45 GPIB (Rear): IEEE-488 |

External User I/O Port

Analog and Digital Programming |

25-pin D-sub DB-25, female Referenced to Earth ground; isolated from the DC input See User Manual for pin layout |

| Specification | Value |

|---|---|

Resolution

All Modes |

16-bit, 0.0015% |

Accuracy

Programming and Measurement |

Voltage: ±0.1% of full scale voltage rating Current: ±0.2% of full scale current rating Power: ±0.3% of full scale power rating Resistance: ±0.3% of full scale resistance rating |

Rise/Fall Time

Maximum |

Voltage Mode: 100 ms, 10% to 90% full scale voltage rating Current Mode: 2 ms, 10% to 90% full scale current rating Power Mode: 100 ms, 10% to 90% full scale power rating Resistance Mode: 200 ms, 10% to 90% full scale resistance rating |

Trip Settings Range

Programmable protection limits used to trigger a soft fault shutdown in the event the limit is exceeded by the DC source

|

Over Voltage: 10% to 110% of full scale voltage rating Under Voltage: 0% to 110% of full scale voltage rating Over Current: 10% to 110% of full scale current rating Over Power: 10% to 110% of full scale power rating |

| Specification | Value |

|---|---|

Digital I/O

|

Digital Input Voltage: 5V Digital Input Impedance: 10 kΩ Digital Monitoring Voltage: 5V, 32 mA capacity Digital Reference Voltage: 5V, 20 mA capacity |

Analog I/O

|

Analog Sampling Rate: 2 kHz Analog Programming Voltage: 0-10 V Analog Programming Resolution: 12-bit, 0.025% Analog Monitoring Voltage: 0-10 V, 3 mA capacity Analog Monitoring Impedance: 0.005 Ω Analog Monitoring Accuracy: 0.05% of full scale Analog Reference Voltage: 10 V, 20 mA capacity |

| Specification | Value |

|---|---|

Racking Standard

1.25 kW and 2.5 kW Models Only |

EIA-310 |

Size and Weight

1.25 kW Models |

3U 5.25” H x 19” W x 24” D (13.34 x 48.26 x 60.96 cm) 40 lbs (18.1 kg) |

Size and Weight

2.5 kW Models |

3U 5.25” H x 19” W x 24” D (13.34 x 48.26 x 60.96 cm) 65 lbs (29.5 kg) |

Size and Weight

5 kW Models |

12U Cabinet 30.7” H x 24” W x 31.5” D (78.0 x 61.0 x 80.0 cm) 255 lbs (115.7 kg) |

Size and Weight

7.5 kW Models |

12U Cabinet 30.7” H x 24” W x 31.5” D (78.0 x 61.0 x 80.0 cm) 320 lbs (145.2 kg) |

Size and Weight

10 kW Models |

12U Cabinet 30.7” H x 24” W x 31.5” D (78.0 x 61.0 x 80.0 cm) 385 lbs (174.6 kg) |

Size and Weight

12.5 kW Models |

24U Cabinet 58.25” H x 24” W x 31.5” D (148.0 x 61.0 x 80.0 cm) 500 lbs (226.8 kg) |

Size and Weight

15 kW Models |

24U Cabinet 58.25” H x 24” W x 31.5” D (148.0 x 61.0 x 80.0 cm) 565 lbs (256.3 kg) |

Size and Weight

17.5 kW Models |

24U Cabinet 58.25” H x 24” W x 31.5” D (148.0 x 61.0 x 80.0 cm) 630 lbs (285.8 kg) |

Size and Weight

20 kW Models |

24U Cabinet 58.25” H x 24” W x 31.5” D (148.0 x 61.0 x 80.0 cm) 695 lbs (315.3 kg) |

| Specification | Value |

|---|---|

Ambient Operating Temperature

|

0°C to 50°C |

Storage Temperature

|

-25°C to +85°C |

Humidity

|

Relative humidity up to 95% non-condensing |

Air Flow

|

Front air inlet, rear exhaust |

| Specification | Value |

|---|---|

EMC

|

Complies with 2014/30/EU (EMC Directive) CISPR 22 / EN 55022 Class A |

Safety

|

NRTL Listed, TÜV SÜD Certificate U8 123461 0002 Tested to UL 61010-1:2012/R:2019-07 and CSA C22.2 No. 61010:2012/A1:2018-11 Complies with EN61010-1 and 2014/35/EU (Low Voltage Directive) |

CE Mark

|

Yes |

RoHS Compliant

|

Yes |

Options and Accessories

The following are options and accessories developed specifically for Magna-Power's ALx Series

Accessories

External accessories and integration services are available for Magna-Power products

Integrated Options

Standard integrated options are available for Magna-Power products, allowing the product's performance and communication interfaces to be tailors to the specific application.

CANopen

Option Code: +CAN

Availability:

CANopen communication protocol and dual RJ-45 interface enabling CAN bus communications, popular within automotive applications

EtherCAT

Option Code: +ECAT

Availability:

EtherCAT communication protocol and dual RJ-45 interface for high-performance communication in factory automation, motion control, and robotics

EtherNet/IP

Option Code: +EIP

Availability:

EtherNet/IP communication protocol and dual RJ-45 interface with EIS profile for industrial automation, commonly used in Allen Bradley, Schneider Electric, and Omron PLCs

IEEE-488 GPIB

Option Code: +GPIB

Availability:

IEEE-488 General Purpose Interface Bus (GPIB) communication interface providing full command support and compatibility with other GPIB devices

LXI TCP/IP Ethernet

Option Code: +LXI

Availability:

TCP/IP Ethernet communication protocol and single RJ-45 interface, certified to the LXI Class C standard, for socket communications using conventional computer networks

Modbus-TCP

Option Code: +MTCP

Availability:

Modbus-TCP communication protocol and dual RJ-45 interface with full command set support as Modbus commands

PROFINET

Option Code: +PROF

Availability:

PROFINET communication protocol and dual RJ-45 interface for industrial automation, commonly used in Siemens PLCs

Downloads

The following downloads are for the Serie ALx: