Ruggedized MagnaDC Power Supplies Now Compliant with RTCA/DO-160G Vibration

Magna-Power has extended the Ruggedization option’s ratings on the new SLx Series to include RTCA/DO-160G vibration rating for airborne applications.

While all Magna-Power products are designed to survive handling by common carriers for worldwide transportation–often a formidable challenge–certain applications demand even further enhanced shock and vibration ratings. Magna-Power’s Ruggedization (+RUG) option has provided a cost-effective way to achieve MIL-STD shock and vibration ratings with a relatively nominal adder, typically for ground-based applications such as: powering lasers and radars aboard mobile vehicles, geophysics exploration in remote areas, skid-mounted or containerized drilling solutions, and aboard ships to power underwater vehicles.

Magna-Power has now extended the Ruggedization option’s ratings on the new SLx Series to include RTCA/DO-160G vibrations rating for airborne applications, providing economical commercial of the shelf (COTS) highly power dense solutions using the company's standard products, where specialty products were previously required.

The SLx Series features many manufacturability upgrades that offer additional physical robustness for shock and vibration, which laid the groundwork for this extended rating. Nearly all ribbon connectors were replaced with latching Pico-Clasp connectors, which provide additional security through a tabbed release. In addition, many larger daughter assemblies were integrated into primary assemblies, reducing mechanical and board interfaces. Finally, a new epoxy staking method was developed for the Ruggedized option in accordance with IPC-A-610 guidelines.

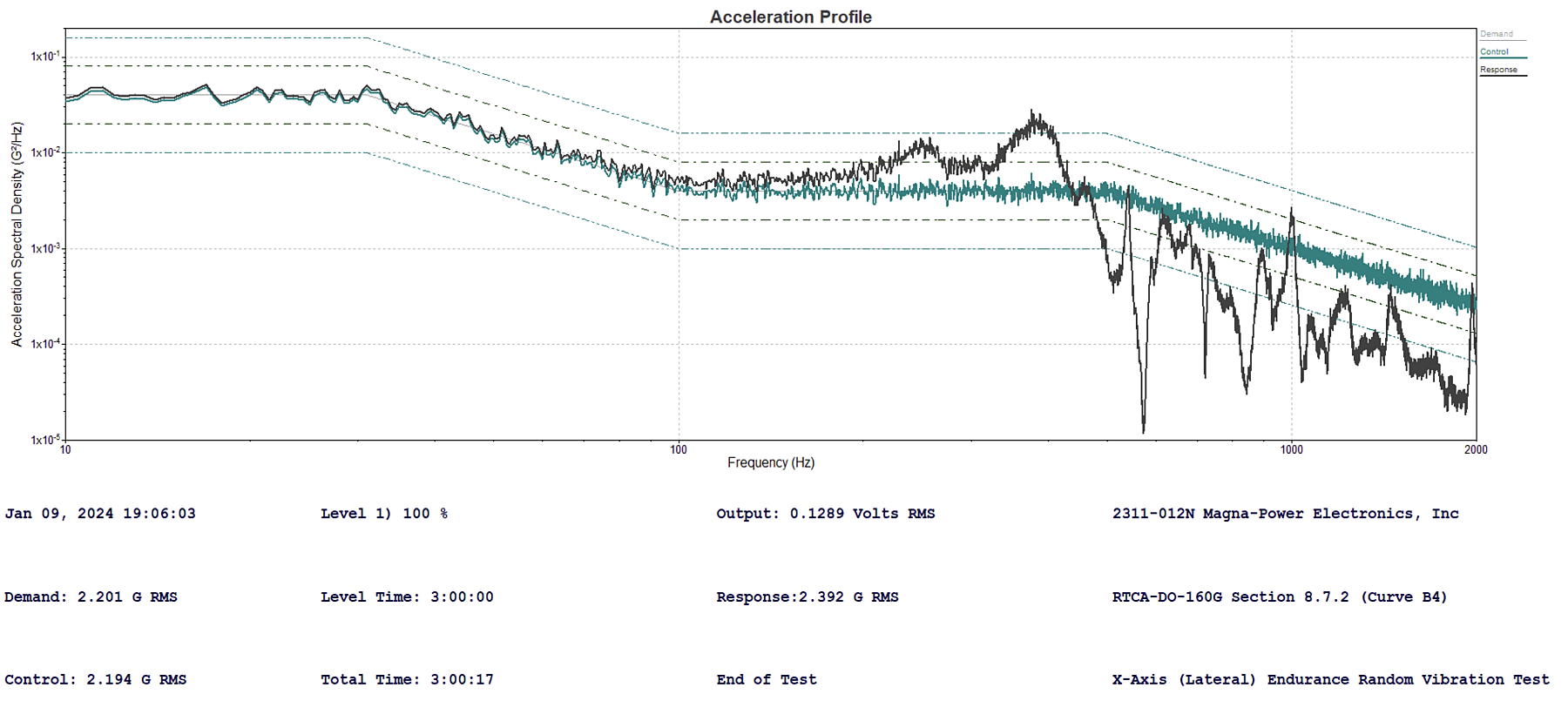

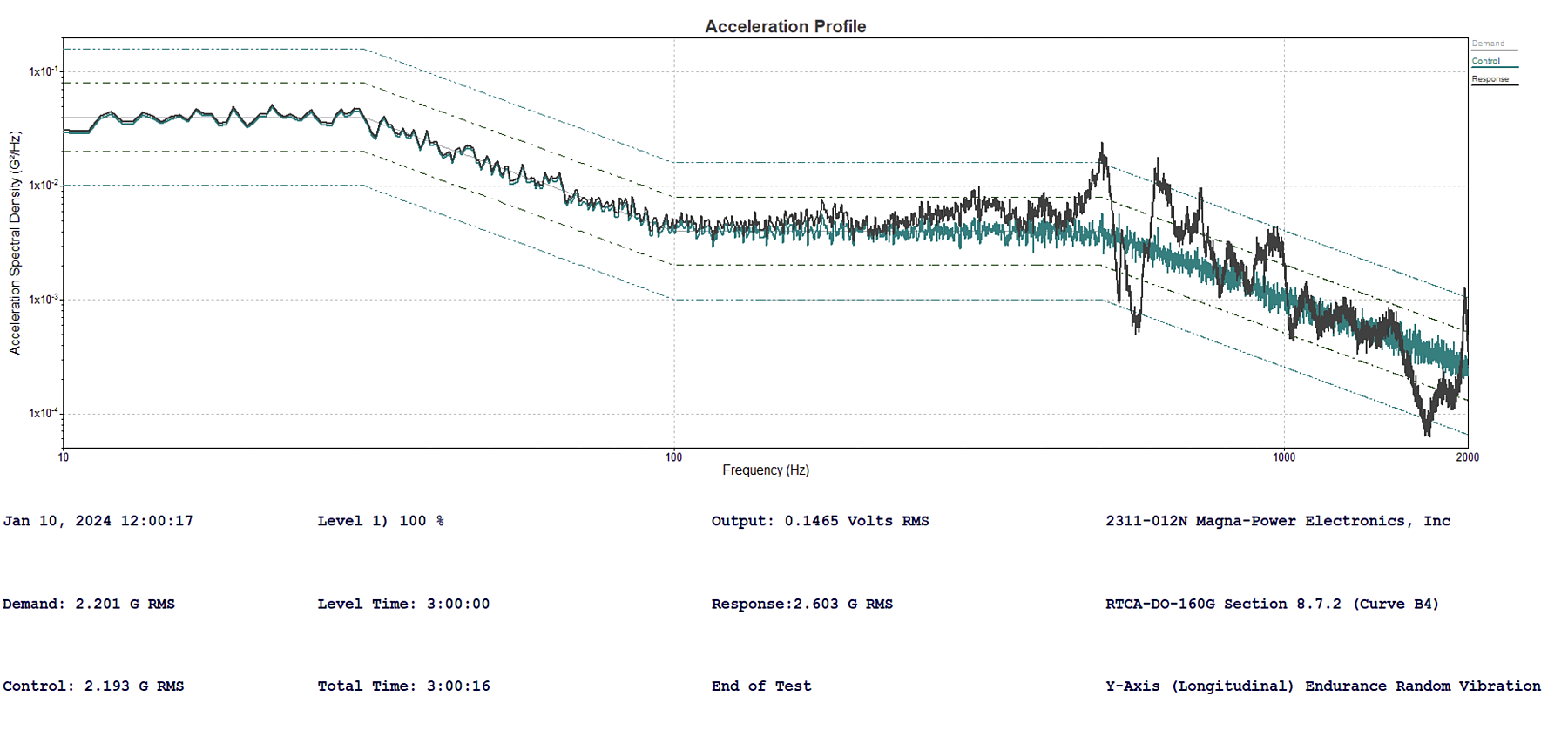

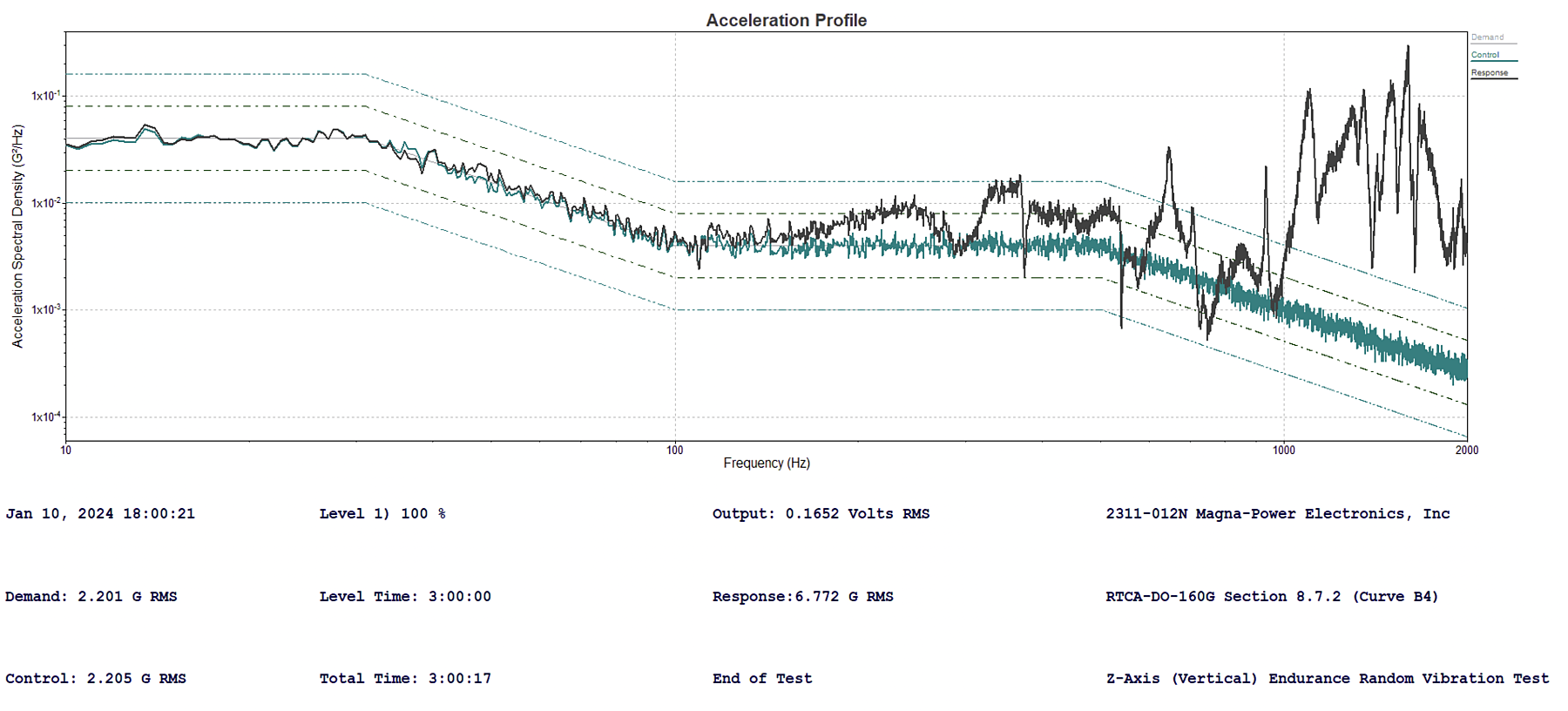

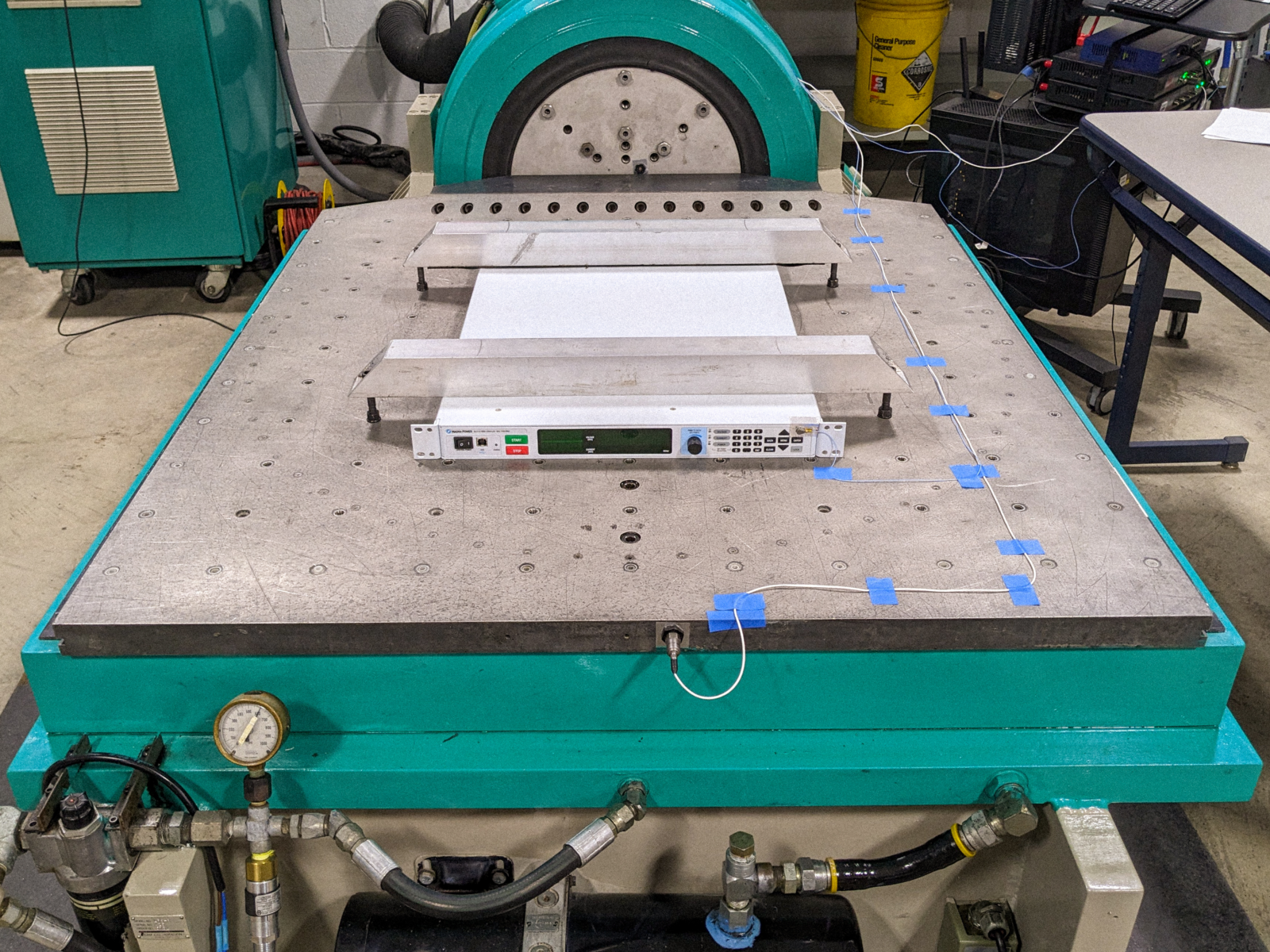

RTCA DO-160 vibration testing determines whether equipment meets performance standards when subjected to the vibration profiles of a fixed-wing propeller aircraft, fixed-wing turbojet, turbofan, and propfan aircraft and helicopters. Section 8.0 of RTCA DO-160, Vibration Testing, defines various profiles and intensities for testing. The SLx Series was tested at an independent laboratory to comply with Profile B4, which subjects the product to random vibration test curves with an average force of 2.2 Grms. For elevated altitude applications, the SLx Series also comes standard with the capability to disable load-dependent cooling, to force fans to maximum.